| Posted: Aug 11, 2015 | |

Foldable glass |

|

| (Nanowerk Spotlight) Have you ever heard about foldable glass? | |

| Exactly. | |

| Glass is notorious for its brittleness. Although industry has developed ultra-thin (∼0.1 mm), flexible glass (like Corning's Willow® Glass) that can be bent for applications liked curved TV and smartphone displays, fully foldable glass had not been demonstrated. Until now. | |

| Usually, the thinner a substrate or device is, the more flexible it becomes. Folding can be considered an extreme case of bending. Researchers already made progress towards foldable electronics ("Nanotechnology research produces foldable graphene electronics on paper"), origami-foldable solar cells, and foldable Li-ion batteries. | |

| "The use of ultrathin substrates (usually with a thickness of 1-2 microns) is especially suitable for conformable, patch-like skin sensors or devices, whereas it's not so suitable for displays or other applications due to its mechanical instability," Dahl-Young Khang, an Associate Professor in the Department of Materials Science and Engineering at Yonsei University, tells Nanowerk. "Such ultrathin substrates – and devices fabricated on it – can easily be buckled or crumpled." | |

| Khang and his group have now demonstrated substrate platforms of glass and plastics, which can be reversibly and repeatedly foldable at pre designed location(s) without any mechanical failure or deterioration in device performances. | |

| The findings have been reported in the July 21, 2015 online edition of Advanced Materials ("Glass and Plastics Platforms for Foldable Electronics and Displays"). | |

|

|

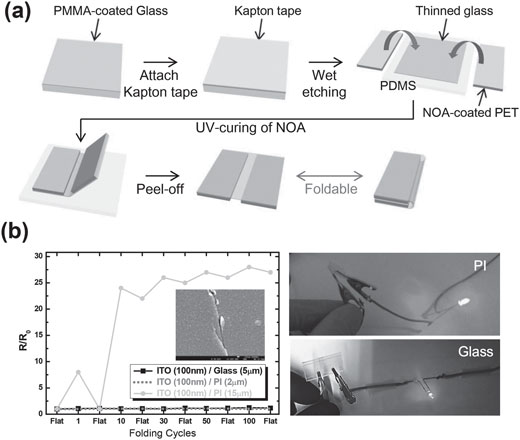

| Schematic drawing of steps involved for the foldable glass platform, which is composed of thick, non deformable parts connected by thinned, foldable one. (Reprinted with permission by Wiley-VCH Verlag) | |

| "We have engineered the substrates to have thinned parts on which the folding deformation should occur," Moon Jong Han, first author of the paper a graduate student in Khang's lab, says. "This localizes the deformation strain on those thinned parts only." | |

| He adds that this approach to engineering substrates has another advantage regarding device materials: "There is no need to adopt any novel materials such as nanowires, carbon nanotubes, graphene, etc. Rather, all the conventional materials that have been used for high-performance devices can be directly applied on our engineered substrates." | |

| Intriguingly, even ITO (indium tin oxide), a very brittle transparent conducting oxide, can be used as electrode on this novel foldable glass platform. | |

| The design concept of this foldable platform comes from the methodology used in folding mats and hinge-less oriental folding screens, all of which commonly have pre-defined linear regions much thinner than the adjacent thick, rigid parts. | |

| This selective thinning of substrates for foldability, contrary to ultrathin substrates over the whole sample, is a novel approach. By applying this strategy, it now has become possible to even fold notoriously brittle glass substrates. | |

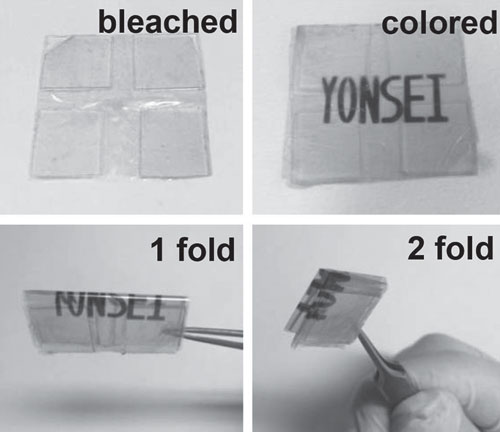

| Furthermore, the whole sample can be folded twice (dual folding), folding along the x-direction first followed by another folding along the orthogonal y-direction, which reduces the sample size down to 1/4 of its original size. | |

|

|

| Photographs of dually foldable EC display on PET platform. (Reprinted with permission by Wiley-VCH Verlag) | |

| The width of the thinned parts, the gap width, plays the key role in implementing dual foldability. The other key element is the asymmetric design of the gap width for the second folding. | |

| In their paper, the scientists suggest a simple design equation for the dual folding which they found to agree very well with experimental data. | |

| A dual fold might come especially handy for electronic devices that need portability and large size at the same time. A large-area display, photovoltaics, sensors, or detectors can easily be transported in small footprint by dual folding, then they can be expanded into large size upon use. | |

| "Although our approach relieves the mechanical instability a lot, it was not possible to completely overcome the instability by those thinned part(s) of the substrate," cautions Han. "This is a kind of ?fundamental dilemma?. In other words, the foldability demands thin or ultrathin substrates, while mechanical stability requires the opposite, thick substrates. Although these contradicting requirements can be alleviated to some degree by devising the foldable platform, it is not possible to completely solve the contradiction out." | |

| Thus, in actual foldable hand-held devices, a proper foldable housing (the team already has filed a patent on a foldable housing design) would be necessary not only for mechanical stability but also for the integration of other elements required for electronic devices such as battery, circuit board, etc. | |

| Khang and his team are are now trying to apply this design principle to other devices, such as solar cells and sensors and, together with industrial partners, make prototype foldable devices. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|