| Mar 27, 2019 | |

Iontronic sensing paper provides a new touch for pressure sensors (w/video) |

|

| (Nanowerk Spotlight) Because it is easily available, low-cost, insulating, flexible, and portable, paper has been recognized as a particular class of supporting matrix for accommodating biological or chemical sensing materials. You have probably come across pH papers, blood glucose-sensing strips, and early pregnancy detection kits. | |

| Thanks to more recent developments in this area, nanotechnology-enabled, paper-based sensors promise to be simple, portable, disposable, low power-consuming, and inexpensive sensing devices that will find ubiquitous use in medicine, detecting explosives, toxic substances, and environmental studies. Thanks to their fibrous structure, papers can be modified with functional additives, such as carbon-derived materials (e.g., carbon nanotubes and graphene), conductive polymers, and metallic nanocomposites, leading to new functionalities and sensing modalities. | |

| For an overview of the many applications being developed with paper sensors, see these examples in our previous Nanotechnology Spotlights: "Simple nanotechnology paper sensor for detecting toxins in water"; "Biosensors printed on bioactive paper"; "An optical sensor platform based on nanopaper"; "Cheap nanotechnology paper-based gas sensors"; or "Wearable health monitor based on household paper". | |

| Previously reported pressure-sensitive papers, along with the pressure sensors made of them are primarily based on three existing sensing mechanisms, i.e., resistive, capacitive, and triboelectric. | |

| "Recently, a brand-new mechanism of pressure sensing, known as flexible iontronic sensing (FITS), has been introduced, which utilizes pressure-induced capacitive changes between electrodes and ionic surfaces," Tingrui Pan, a professor at UC Davis, tells Nanowerk. "Notably, unlike the conventional resistive and capacitive sensing modalities, the iontronic pressure sensor, based on the unique FITS mechanism, has shown extremely high sensitivity and resolution, while the parasitic noises can be largely negligible, given its ultrahigh signal-to-noise ratio." | |

|

|

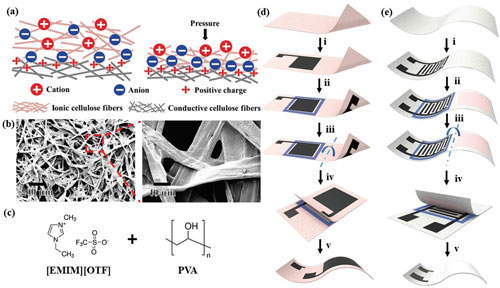

| a) The pressure-response mechanism of the iontronic pressure sensing paper (ISP) device in which the fibrous ionic fibers is used as the ionic region and the conductive fibers is used as the conductive region; b) the SEM images of the ionic region of the ISP; c) illustration of the molecular structures of the ionic liquid and the polymer matrix; d) the preparation of the ISP device with a sandwich structure: i) printing a top electrode onto the ionic paper, ii) printing a bottom electrode on the back side of the ionic paper, iii) printing adhesive patterns to integrate, iv) folding over to form the sandwich structure, v) final packaging and integration; e) the preparation of the ISP device with a bilayer structure: i) printing interdigital electrodes on a regular paper, ii) printing ionic ink onto the designed region, iii) printing adhesive patterns to integrate, iv) folding over to form the bilayer structure, v) final packaging and integration. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| In their new paper in Advanced Functional Materials ("All-in-One Iontronic Sensing Paper"), Pan and his collaborators introduce a single-sheet iontronic paper substrate with both ionic and conductive patterns as an all-in-one flexible sensing platform. | |

| "Our novel sensing paper extends the iontronic sensing principle to a more adaptive material system, with direct printability, custom cuttability, and 3D foldability at a low cost – just as regular paper," Pan points out. | |

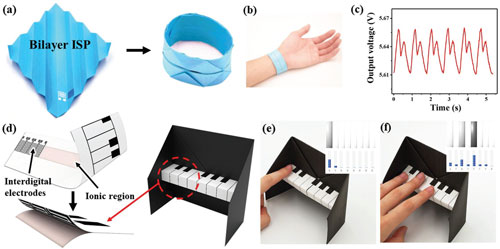

| It now has become possible to construct pressure sensing platforms via simple printing, cutting, gluing and folding. And since pressure sensing device are no longer restricted to a planar device, 3D pressure sensing origami to detect spatial pressure are now also possible. | |

| Basically, everything and every surface around us can be transformed into a sensing structure – on smart toys, smart packaging, personal wearables, disposable electronics, wallpaper, furniture, etc. or as flexible human?machine interfaces. | |

| "This opens up a future where everything we touch has tactile ability, and people can communicate with any object by touching, pressing and flapping, offering a comprehensive human-object interface via visual, auditory and tactile inputs," notes Pan. | |

|

|

| a) The preparation of the ISP origami bracelet using printing and folding; b) the ISP origami bracelet is wearable for pulse monitoring, c) the pulse wave signal collected by the ISP origami bracelet; d) the preparation of the ISP origami piano with pressure-sensitive keyboard; e,f) the ISP origami piano with force-sensing function can detect the pressure and control the volume. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) (click on image to enlarge) | |

| Watch a video of the ISP origami piano: | |

| There are still a few kinks to sort out, though. For instance, there are interconnection problems: Current signal interconnection between paper electronics and signal processing systems via conductive gluing still has reliability issues. The team is confident that low-temperature soldering and a specific paper-FPC (flexible printed circuit) interconnect slot can solve this problem. | |

| "Sensor device research is no longer just about the sensing elements; energy supply, signal processing, and electronic circuitry should be considered and such an integrated device should also be compatible with skin, cloth, and so on in shape, modulus and functions," Pan concludes. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|