| Posted: Oct 07, 2015 | |

Open source and DIY hardware for DNA nanotechnology labs |

|

| (Nanowerk Spotlight) Setting up or upgrading a lab to conduct state-of-the-art DNA nanotechnology is not an inexpensive undertaking. The hardware alone can easily set you back several hundreds of thousands of dollars. | |

| Analogous to the open-source software approach (think Linux or Apache), increasingly instruments and specialized equipment designs are also developed as part of a growing open source scientific hardware (OSSH) movement. | |

| Previously, we have already reported on how a group of nanotechnology students built a low cost (less than $500) Atomic Force Microscope using LEGO, or a cheap, homemade benchtop photolithography system for less than $30. | |

| Adding to the list, a recent article in the Journal of Biological Methods ("Open source and DIY hardware for DNA nanotechnology labs") presents three examples of open source/do-it-yourself (DIY) technology with significantly reduced costs relative to commercial equipment. | |

| "There are many reasons for exploring an open source approach to laboratory equipment," says Peter B. Allen, an Assistant Professor at the University of Idaho, and senior author of the paper. "Open source equipment is more flexible and usually less expensive than the equivalent commercially produced experimental apparatus. While cost savings is an important consideration in and of itself, it also allows for researchers to take a smaller risk in trying a new procedure or exploring a new research interest." | |

| A gel scanner design for scanning electrophoretically separated DNA | |

| Here, an inexpensive ($100) office scanner was converted to fluorescence detection, achieving comparable sensitivity to a commercial instrument. | |

|

|

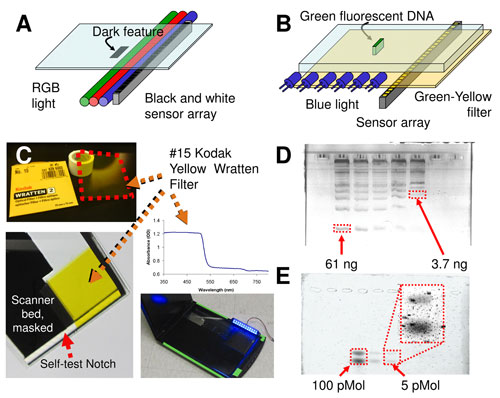

| Design and performance of the converted gel scanner. A. Diagram shows the operation of the original office scanner. Red, green, and blue LEDs illuminate a subject and a color image is reconstructed by a sensor. B. Diagram shows how a modified fluorescence scanner operates with the blue LED only and a filtered sensor to collect green and red light. C. The elements of the gel scanner are shown including a digital photograph of the filter, the absorption spectrum of the filter, the position of the filter on the underside of the scanner bed, and the assembled scanner with side-on illumination. D. Representative gel scans are shown (top) of an a agarose gel run with a 100 bp ladder stained with GelGreen and (bottom) a PAGE gel with a dilution series (100 pM, 10 pM, 5 pM) of two species of fluorescein-DNA. The inset shows a contrast-enhanced, magnified region containing the faint 5 pM bands. (© The Journal of Biological Methods) (click on image to enlarge) | |

| Although the original scanner itself is commercial, the researchers in their paper present the source code for the conversion with step-by-step instructions and a detailed list of materials required. | |

| In summary: Green and red illumination sources were disabled. Green or red light would pass through the filter and cause unacceptable levels of background live reflected light. The blue light emitted by the scanner was preserved so that the scanner would pass its internal self-checks. A yellow wratten filter is then taped to the underside of the scanner bed. Side-on blue illumination (rather than the scanner's internal blue LED) was then added for efficient exultation to increase the signal-to-noise. | |

| A gel mold for horizontal polyacrylamide gel electrophoresis (PAGE) | |

| Polyacrylamide gel electrophoresis (PAGE) analysis and purification of DNA oligonucleotides is a prerequisite for many applications of DNA. DNA nanotechnology is usually built on the basis of smaller DNA fragments (under 100 bases). This requires the use of PAGE. | |

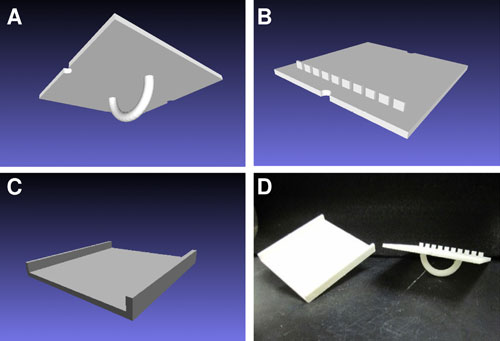

| The authors write that, with the advent of 3D printing, a gel casting form can be easily manufactured that allows for the polymerization of an acrylamide gel in the exact format necessary for horizontal gel rigs. Other techniques for creating gels appropriate for horizontal PAGE have been published. But this one has the distinction of using an open source, 3D printed gel mold which can be ordered or modified as needed. | |

|

|

| Methods for casting PAGE gels for use in horizontal electrophoresis setup. A and B. 3D renderings of the top part of a casting mold for horizontal PAGE gels. C. 3D rendering of the bottom part of the casting mold. D. Digital photograph of the 3D printed casting mold for PAGE gels. (© The Journal of Biological Methods) (click on image to enlarge) | |

| A design for a homogenizer which can be attached to any reciprocating motor | |

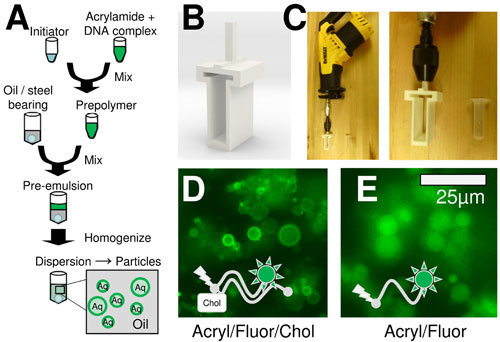

| This homogenizer can be used to generate colloidal particles from polyacrylamide which can be useful for multiple DNA-based applications including affinity chromatography, NexGen sequencing, or sample enrichment. This is considerably more customizable and less expensive than commercial sources of DNA-coated particles. Both designs can be downloaded, modified, and 3D printed in-house or ordered from a prototype manufacturer. | |

|

|

| 3D printed homogenizer design and operation. A. Diagram shows how dispersion polymerization particles were generated. B. 3D rendering shows the design of the 3D printed homogenizer. C. Digital photographs show how the 3-D printed homogenizer is assembled using a reciprocating motor. D. Fluorescence micrograph shows particles generated with DNA bearing the acrydite, cholesterol, and fluorescein modifications. E. Fluorescence micrograph shows particles generated with DNA bearing the acrydite and fluorescein modifications (i.e. without cholesterol). Scale bar is 25 µm for both images. (© The Journal of Biological Methods) (click on image to enlarge) | |

| The cost savings of building rather than buying a piece of equipment can range from 50 to 90%. For the three examples described above, the savings are about 90% in each case. | |

| In the case of the scanner (cost ∼$200), it replaces a gel document system that costs several thousand dollars (greater than $2,000, used). In the case of the horizontal gel casting mold (cost ∼$30), it replaces a second gel rig that costs several hundred dollars (typical cost ∼$500-$1000 depending on size). In the case of the homogenizer (cost ∼$200 including motor and speed controller), it replaces a commercial tissue homogenizer that costs several thousand dollars (>$5000). | |

|

If you are interested in this topic, a more comprehensive list of OSSH has been published in book form: Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs |

|

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|