| Posted: Jul 15, 2014 | |

Photorealistic plasmonic printing with aluminum nanostructures |

|

| (Nanowerk Spotlight) The Lycurgus cup was created by the Romans in 400 A.D. Made of a dichroic glass – the dichroic effect was achieved by including gold and silver nanoparticles in the glass – the famous cup exhibits different colors depending on whether or not light is passing through it; red when lit from behind and green when lit from in front. It is also the origin of inspiration for contemporary nanoplasmonics research – the study of optical phenomena in the nanoscale vicinity of metal surfaces (read more: "Quantum plasmons demonstrated in atomic-scale nanoparticles"). | |

|

|

| Lycurgus cup. | |

| The physical phenomenon of plasmon resonances in small metal particles has been used for centuries. They are visible in the vibrant hues of the great stained-glass windows of the world. More recently, plasmon resonances have been used by engineers to develop new, light-activated cancer treatments and to enhance light absorption in photovoltaics and photocatalysis. | |

| Aluminum has gained interest in the field of nanoplasmonics not only because it is abundant and costs a fraction of gold or silver, but also because it allows field-enhancement effects into the ultraviolet. However, it has broader resonances than silver and gold, and forms an oxide layer. Both these effects are undesirable in applications such as biosensing, in which signal strengths are reduced in the presence of resistive losses and oxide barriers. | |

| However, color printing based on the plasmon resonances of aluminum nanostructures could benefit from these properties. Researchers in Singapore have now demonstrated, for the first time, the utility of aluminum nanostructures for ultrahigh definition plasmonic color printing. | |

| The team, led by Joel Yang, an assistant professor at Singapore University of Technology and Design, and Shawn Tan, a scientist at the Institute of Materials Research and Engineering (IMRE), A*STAR, has reported their findings in the June 13, 2014 online edition of Nano Letters ("Plasmonic Color Palettes for Photorealistic Printing with Aluminum Nanostructures"). The work was performed in collaboration between SUTD, IMRE and National University of Singapore (NUS). This is a study for color generation and the design principle of plasmonic color pixels. | |

| The reliance on dyes and chemicals for colorants is fraught with problems such as the fading of dyes due to chemical reactions; the need for different dyes for different colors; and the effect of dye-related chemical waste on the environment. | |

| Colors from plasmonic nanostructures circumvent these issues. However, unlike pigment-based colors which have very well-established color systems available, the color system for plasmonic colors arising from metal nanostructures has yet to be defined. | |

| Unlike color pigments which can be overlaid to generate new secondary colors, discrete metal nanostructures rely on size, shape and relative positioning to generate new colors. In this work by the Singaporean team, they introduced a simple approach to generating new colors from plasmonics nanostructures through spacing and size, and introduced the first plasmonic color system for aluminum. | |

| "Aluminum becomes an attractive material for plasmonic color printing owing to its neutral tint, durability, resonance insensitivity to size, high reflectance in the visible regime, and global abundance, therefore low cost," Tan tells Nanowerk. "Unlike gold and silver, the colors in the visible wavelength regime for aluminum are manifested by nanodisks with feature sizes accessible for mass production. With aluminum nanodisks as our model system, we developed and validated a framework for color generation in the context of plasmonic colors that serve to establish a plasmonic color system." | |

| As the team demonstrates in their latest work, aluminum nanostructures can be engineered to produce a broad range of colors, thus making it suitable for ultra-high resolution color printing previously demonstrated in silver and gold. | |

| One key finding from this work is that the process of color mixing in nanometallic structures results in 'purer' colors than the basic color palette. | |

| "Specifically, with aluminum as the plasmonic material, we expand the range of printable plasmonic colors from ∼15 colors to more than 300 colors by employing newly defined color generation strategies," says Yang. | |

|

|

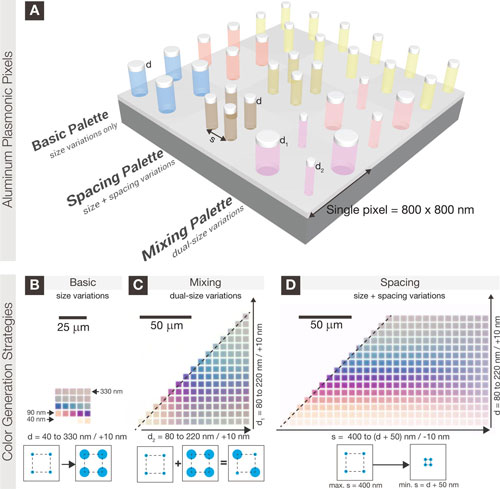

| (A) Schematic illustrating the architecture of aluminum plasmonic pixels. Isolated aluminum nanodisks sit atop HSQ nanopillars. The substrate is coated with an aluminum back reflector. Actual experimental images of fabricated color palettes with different layout strategies: (B) basic color palette with only size variations (d = 40 to 330 nm) at a step size of 10 nm and a fixed pitch of 400 nm between nanodisks, (C) mixing color palette with two size variations (d1, d2 = 80 to 220 nm) among four nanodisks within an 800x800 nm pixel, at a step size of 10 nm and a fixed spacing of 400 nm between nanodisks, and (D) spacing color palette with both size variations (d = 80 to 220 nm) and spacing variations (s = d + 50 to 400 nm) among four nanodisks within an 800x800 nm pixel, at a step size of 10 and 20 nm, respectively. Optical images were normalized to a white background. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| Another advantage for color printing applications is the impermeable native oxide layer that is formed by aluminum, which forms a protective coating that preserves the colors. | |

| For their technique, the team fabricated 95 nm-tall nanodisks (nanopillars) of varying diameters on a silicon substrate using electron-beam lithography patterning. Once a 20 nm-thick aluminum layer is deposited onto the nanodisk patterns, the nanodiscs exhibit plasmonic colors. | |

| Each plasmonic nanopixel consists of four nanodisks arranged in a square arrangement. Positioning different-sized disks within a pixel, changing the distance between them, and their position within the pixel affected the colors they produced. This allowed the researchers to fine-tune the colors and achieve their 300+ color palette. | |

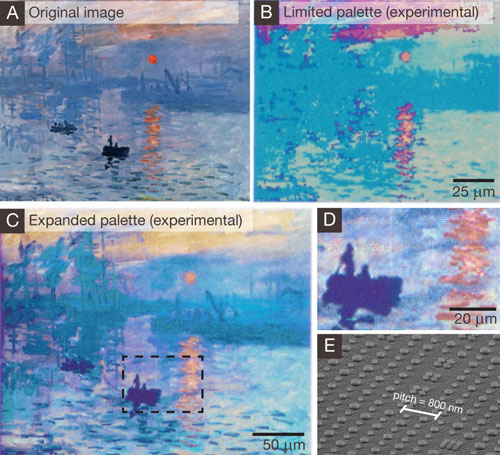

| To highlight the range of colors that could be generated, the team printed Claude Monet?s painting of Impression, Sunrise in which they utilized subtle color variations. | |

|

|

| Reproduction of Monet?s Impression, Sunrise using the expanded palette by color toning and mixing strategies. (A) Original input image adapted with permission from Musee Marmottan Monet, Paris, France / Giraudon / Bridgeman Images. (B) Reproduction using only the limited palette of ?primary plasmonic colors? falls short of the original image. (C) Realistic reproduction of the artwork using an expanded palette of colors, allowing for the subtle variations in tone and color in the original to the replicated. (D) Higher magnification image of dotted box in (C) highlighting the brush strokes that are resolved in the plasmonic painting. (E) Tilted SEM image of pixels showing how the colors observed in the plasmonic painting are the manifestation of a predefined structural layout. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| Technologically, using a significantly more cost-effective metal has potential for moving this technology forward towards adoption. | |

| "We have shown here that color prints can be created with high-resolution and preserved fidelity at the microscale, where each print is custom printed using a focused beam of electrons," Yang concludes. "Scaling up this technology would be the next logical step, i.e. to demonstrate that these features can be suitable for larger area prints, and large numbers of samples." | |

| The team envisions this work to have a direct impact in security and counterfeiting applications, as well as in product branding and authentication. This technology could be further extended to holography and data storage applications as well. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|