| Posted: Apr 15, 2016 | |

New phenomena in the ultrasonic scattering in nanofluids |

|

| (Nanowerk Spotlight) Ultrasonics is a promising, non-invasive characterization technique for fluids. The scattering of ultrasound through colloidal suspensions allows determination of accurate particle size distribution, density, and concentration. Controlling these properties enables accurate characterization of nanomedicine drugs and understanding of nanoparticles present in biological systems. Ultrasound is particularly helpful in analyzing optically opaque samples, which have to be heavily diluted in order to be analyzed with optical methods. | |

| The suspension of nanoparticles has many uses, e.g. in foods, cosmetics, healthcare products, agrochemicals, and drug delivery systems, and a way of measuring their properties is a crucial element of the production process and of great importance in a number of industries. | |

| New work by scientists at Loughborough University in the UK and Université du Havre in France, demonstrates for the first time new phenomena in the ultrasonic scattering in nanofluids. | |

| Reporting their findings in Nanoscale ("Experimental verification of nanofluid shear-wave reconversion in ultrasonic fields"), the team shows that shear-mode effects cannot be neglected as one approaches the nanoscale and their complex dependencies upon particle size, concentration, applied frequency, and density contrast between the suspended particles and the suspending medium are carefully investigated. | |

| "In order to understand the measurements we make, we need to use a model, a set of equations and calculations which tell us how the properties of the particles and fluid affect the loss of amplitude and speed of the wave," Dr. Valerie Pinfield, group leader at Loughborough, explains to Nanowerk. "The model we use has two parts: a multiple scattering theory, and a model for the scattering from a single particle." | |

|

|

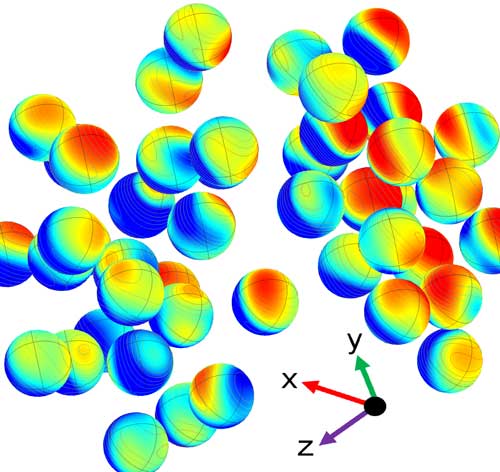

| As the size of the solid particles in a suspension become less than a few micrometres and concentration levels increase, complicated shear wave reconversion phenomena happen around the particles – leading to a reduced attenuation of an ultrasonic beam. (Image: Loughborough University) | |

| In the past, the model used by researchers has been limited because it made some approximations about the shear waves which are produced at the particles; it assumed that those waves die away in a very short distance, and do not have any effect on the particles nearby. Although they do die away in a very short distance, they can affect the neighboring particles when the suspension is very concentrated (i.e. there are a lot of particles in a small space). | |

| "The shear waves themselves can be scattered by particles nearby and may be partly converted back into a compressional wave (an ultrasonic wave)," Pinfield notes. "This means we did not lose as much of the energy from the compressional wave as we thought. The process of wave conversion and re-conversion is referred to as multi-mode scattering and for many years, its effect has been ignored because we did not have a suitable model to calculate it – until now." | |

| The outcome of the team's work is a model in a form which can be used in online ultrasonic instrumentation. This will enable ultrasonics to be used with confidence as a process monitoring technique in a wide range of industrial contexts. It becomes possible to obtain knowledge of the physical properties of a nanofluid based upon its attenuation spectra. | |

| These models are of interest in the mathematical physics community for homogenization of advanced material properties (composite materials/metamaterials), as well as the non-destructive evaluation research field. In addition, they have relevance for the use of ultrasonics as a research technique for the study of novel suspended materials such as nanoparticles, micellar materials, some drug delivery systems. | |

| Dr. Michael Forrester, first author of the paper, states that "We use two ultrasonic spectrometers (a Digusonic DSX and a Malvern Ultrasizer) and compare the result to our new multiple scattering model, which is very computationally efficient, making it ideal for implementation in particle characterisation and sizing systems – especially for suspensions that are optically opaque and impossible to analyze using traditional light scattering techniques. Indeed, our model is very successful even at high concentrations – tested up to 25% volume/volume – where other models break down." | |

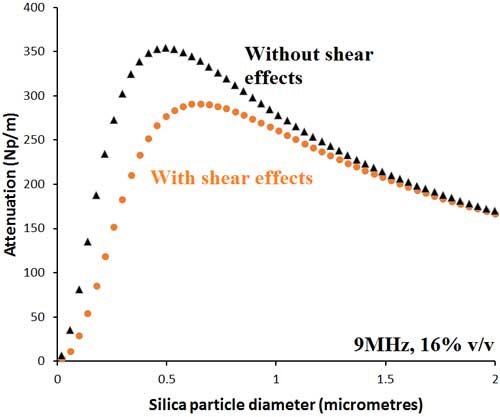

| He notes that, without inclusion of shear-wave reconversion effects, the attenuation is found to be much higher than experimental observation. | |

| Fluid containing solid particles can scatter ultrasonic waves by the particles redirecting some of the wave in other directions. These ultrasonic waves – travelling at frequencies higher than humans can perceive – are compressional waves and the scattering by the particles can be converted into shear waves. | |

| This is the team's primary discovery, alongside the experimental proof and a new multiple-scattering model that can be incorporated into an industrial system to accurately represent the sound attenuation. | |

| The shear wave phenomena occur in concentrated suspensions and become dominant as the system approaches the nanoscale. These processes take energy away from the ultrasonic wave which causes a reduction in its amplitude. | |

| By measuring the attenuation (loss in amplitude) and the wave speed for an ultrasonic wave travelling through the suspensions, it is possible to find out the concentration of particles, how big they are, or something about their properties e.g. their density. | |

|

|

| The attenuation (Np/m) is plotted for different sizes of silica particles in an aqueous medium, with shear-wave phenomena included (orange dots) and without (black triangles). The frequency of the applied ultrasonic field is 9MHz and the concentration of silica is 16% v/v. (Image: Loughborough University) | |

| Whereas multiple scattering models of the past, such as the Lloyd Berry model, neglected shear wave effects, Forrester and his collaborators show without doubt that they cannot be neglected in the analysis of nanofluids with ultrasonics. | |

| The team's model matches experimental results almost exactly in the frequency ranges investigated – 1-20MHz, which is the range valid for medical and biological analyses. | |

| "In this frequency regime, previous multiple scattering models have failed at comparatively low concentrations and at the lower range of the frequency scale, whereas we find that the new model very accurately matches the experiments," says Forrester. "We examine in detail silica particles of 100nm, 214nm, 430nm and 1000nm in water suspensions and measure the attenuation over the broadband of frequencies and concentrations." | |

| This work is essential to help fullfil the potential for use of ultrasonic testing in nanofluids, showing the regimes where shear-modes have greatest effect; to that end, the scientists have identified peaks occurring in the attenuation at specific particle sizes and concentrations. | |

| In this present work, the researchers have investigated the frequency regime with great success up to 20MHz. Going forward, they aim to study higher frequencies and find the limitations of the modelling. | |

| Online monitoring of suspended particulate systems is an extremely widespread need across many industries, for example food, healthcare, chemical, agrochemical, petrochemical, healthcare, nuclear etc. In particular, there is a challenge with the monitoring of highly concentrated suspensions, for which many existing process analytical technologies are unsuited. | |

| Ultrasonics as a technique lends itself to online monitoring since it does not rely on sample dilution as do other techniques. However, the limitations of existing models for data interpretation preclude the use of ultrasonics in many online monitoring applications particularly those involving highly concentrated suspensions (for example in nuclear waste). | |

| "Therefore the impact of the development of a reliable model such as ours for ultrasonic monitoring is potentially highly significant, since it would enable its implementation in a wide range of industrial applications," says Forrester. "Improved monitoring leads to better process control, resulting in cost reductions, lower energy use, and potentially improved or novel products." | |

| He adds that ultrasonics also has the potential for significant impact in process monitoring of novel processing techniques such as those currently in design for nanoparticle production in the healthcare and pharmaceutical fields. | |

| "This developing field brings with it new challenges for online process analytical technologies to provide the necessary process control and optimization. Ultrasonic monitoring is well-placed to satisfy these requirements, provided that suitable models are in place to permit usable information to be extracted from measured data," he concludes. "Delivering a workable model which can be implemented into instrumentation is a critical step in achieving this potential impact." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|