Showing Spotlights 217 - 224 of 262 in category All (newest first):

The most common type of modern transistor, and the type of transistor used in integrated circuits, is called a field-effect transistor (FET). The FET is so named because it relies on an electric field to control the shape and hence the conductivity of a 'channel' (the charge carrier) in a semiconductor material. This field causes a second electrical current to flow across the semiconductor, identical to the first weak signal, but stronger. Since the invention of the first transistor in 1947, the vast majority of electronic devices have been based on inorganic semiconductors, which in most cases has been silicon. Due to the demand for lightweight, flexible opto-electronic devices such as displays, solar cells and lasers, organic materials have become an important new class of semiconductor as they combine the virtues of plastics, which can be easily shaped, with those of semiconductors which are the basis of all microelectronics. Organic field-effect transistors (OFETs) have been mainly based on two types of semiconductors: conjugated polymers and small conjugated molecules. A recent review, published in Chemical Society Reviews, provides a general introduction about the current standing in the area of OFETs focusing on the new processable small molecules that have been recently reported for their use as organic semiconductors.

The most common type of modern transistor, and the type of transistor used in integrated circuits, is called a field-effect transistor (FET). The FET is so named because it relies on an electric field to control the shape and hence the conductivity of a 'channel' (the charge carrier) in a semiconductor material. This field causes a second electrical current to flow across the semiconductor, identical to the first weak signal, but stronger. Since the invention of the first transistor in 1947, the vast majority of electronic devices have been based on inorganic semiconductors, which in most cases has been silicon. Due to the demand for lightweight, flexible opto-electronic devices such as displays, solar cells and lasers, organic materials have become an important new class of semiconductor as they combine the virtues of plastics, which can be easily shaped, with those of semiconductors which are the basis of all microelectronics. Organic field-effect transistors (OFETs) have been mainly based on two types of semiconductors: conjugated polymers and small conjugated molecules. A recent review, published in Chemical Society Reviews, provides a general introduction about the current standing in the area of OFETs focusing on the new processable small molecules that have been recently reported for their use as organic semiconductors.

Apr 2nd, 2008

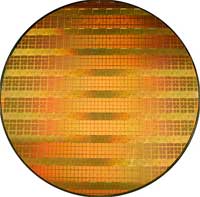

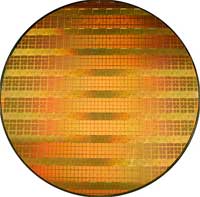

The success of the computer and communications industry is mainly due to the possibility of a large volume and low cost production output: silicon wafers containing myriad micro and nano structures are at the basis of Complementary Metal Oxide Semiconductor (CMOS) technology. A challenge is the realization of spatially ordered nanostructures in silicon that have many interesting applications like photonic crystals to mod the flow of light, chemical sensors, devices to alter the wetting of liquids on a surface, and as capacitors in high-frequency electronics used in mobile phones. The incorporation of such structures on existing silicon chips is greatly desired, and adapting conventional semiconductor nanofabrication to that end is widely pursued. Just a few days ago we wrote about the general aspects and challenges of silicon photonics and today we are taking a look at a specific fabrication challenge. The challenge for researchers is to to obtain photonic crystals with stop bands in the telecommunication wavelength regions, i.e.1330 nm and 1550 nm. To do that, the diameter of these pores must be smaller than 500 nm. The pore to pore distances, also referred to as pitch or interpore distance, must be well below 1 micrometer. Furthermore the depth to diameter aspect ratio of the pores must be as high as possible to obtain photonic crystals with large enough volumes. Researchers in The Netherlands now have demonstrated a method to etch arrays of nanopores in silicon with record depth-to-diameter ratios. These structures are suitable for nanophotonics and were made completely with CMOS compatible technologies, making integration of photonic structures in silicon chips feasible.

The success of the computer and communications industry is mainly due to the possibility of a large volume and low cost production output: silicon wafers containing myriad micro and nano structures are at the basis of Complementary Metal Oxide Semiconductor (CMOS) technology. A challenge is the realization of spatially ordered nanostructures in silicon that have many interesting applications like photonic crystals to mod the flow of light, chemical sensors, devices to alter the wetting of liquids on a surface, and as capacitors in high-frequency electronics used in mobile phones. The incorporation of such structures on existing silicon chips is greatly desired, and adapting conventional semiconductor nanofabrication to that end is widely pursued. Just a few days ago we wrote about the general aspects and challenges of silicon photonics and today we are taking a look at a specific fabrication challenge. The challenge for researchers is to to obtain photonic crystals with stop bands in the telecommunication wavelength regions, i.e.1330 nm and 1550 nm. To do that, the diameter of these pores must be smaller than 500 nm. The pore to pore distances, also referred to as pitch or interpore distance, must be well below 1 micrometer. Furthermore the depth to diameter aspect ratio of the pores must be as high as possible to obtain photonic crystals with large enough volumes. Researchers in The Netherlands now have demonstrated a method to etch arrays of nanopores in silicon with record depth-to-diameter ratios. These structures are suitable for nanophotonics and were made completely with CMOS compatible technologies, making integration of photonic structures in silicon chips feasible.

Mar 26th, 2008

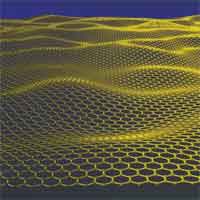

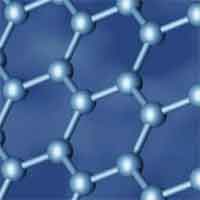

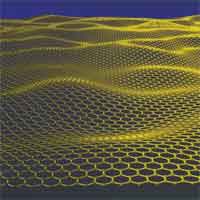

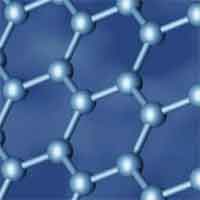

There has been quite a buzz about graphene, a single atomic layer thick, plane of carbon atoms arranged in a honeycomb lattice. Discovered only in 2004, graphene exhibits many exotic properties and currently is considered the most exciting new material system among nanotechnology researchers. This rising star in material science exhibits remarkable electronic properties that qualify it for applications in future optoelectronic devices. In a first experimental study of the thermal conductivity of single-layer graphene, researchers found that on top of many unique electronic properties, graphene also is an extraordinary good heat conductor. Measurements revealed that graphene's near room temperature thermal conductivity, which is in the range from 3500-5300 W/mK, is much higher than that of diamond, the best bulk crystal heat conductor. It appears that the thermal conductivity of graphene is larger than conventionally accepted experimental values reported for individual suspended carbon nanotubes (CNTs) and corresponds to the upper bound of the highest values reported for single-wall CNT bundles. The superb thermal conduction property of graphene is beneficial for its proposed electronic applications and establishes graphene as an excellent material for thermal management also in optoelectronics, photonics and bioengineering.

There has been quite a buzz about graphene, a single atomic layer thick, plane of carbon atoms arranged in a honeycomb lattice. Discovered only in 2004, graphene exhibits many exotic properties and currently is considered the most exciting new material system among nanotechnology researchers. This rising star in material science exhibits remarkable electronic properties that qualify it for applications in future optoelectronic devices. In a first experimental study of the thermal conductivity of single-layer graphene, researchers found that on top of many unique electronic properties, graphene also is an extraordinary good heat conductor. Measurements revealed that graphene's near room temperature thermal conductivity, which is in the range from 3500-5300 W/mK, is much higher than that of diamond, the best bulk crystal heat conductor. It appears that the thermal conductivity of graphene is larger than conventionally accepted experimental values reported for individual suspended carbon nanotubes (CNTs) and corresponds to the upper bound of the highest values reported for single-wall CNT bundles. The superb thermal conduction property of graphene is beneficial for its proposed electronic applications and establishes graphene as an excellent material for thermal management also in optoelectronics, photonics and bioengineering.

Feb 21st, 2008

Due to their exceptional electronic and mechanical properties, as well as their nanoscale size, carbon nanotubes (CNTs) could become the active electronic elements in addressing next generation electronic requirements for which silicon is not a solution. Already, it has been shown extensively that semiconducting CNTs can be made into electronic components such as transistors and switches. Their thermal, mechanical, chemical stability, and large current-carrying capacity make CNTs attractive for applications not only in in electrical interconnects but also field-effect transistors, cold cathode field emitters, and sensors. Some of the problems in developing CNT-based electronic devices have to do with building reliable interconnections between CNTs and external electrical and mechanical systems and in developing a reliable fabrication batch process to allow for industrial-scale mass production that supports the direct manipulation and placement/growth of CNTs at specific locations. Pointing to a possible solution, researchers now have demonstrated controllable and simultaneous wafer-scale assembly of CNT networks by dielectrophoresis.

Due to their exceptional electronic and mechanical properties, as well as their nanoscale size, carbon nanotubes (CNTs) could become the active electronic elements in addressing next generation electronic requirements for which silicon is not a solution. Already, it has been shown extensively that semiconducting CNTs can be made into electronic components such as transistors and switches. Their thermal, mechanical, chemical stability, and large current-carrying capacity make CNTs attractive for applications not only in in electrical interconnects but also field-effect transistors, cold cathode field emitters, and sensors. Some of the problems in developing CNT-based electronic devices have to do with building reliable interconnections between CNTs and external electrical and mechanical systems and in developing a reliable fabrication batch process to allow for industrial-scale mass production that supports the direct manipulation and placement/growth of CNTs at specific locations. Pointing to a possible solution, researchers now have demonstrated controllable and simultaneous wafer-scale assembly of CNT networks by dielectrophoresis.

Feb 18th, 2008

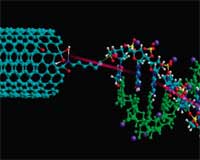

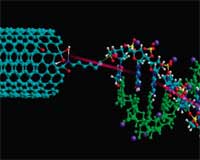

DNA, the blueprint of life, and electronics seem to be two completely different things but it appears that DNA could offer a solution to many of the hurdles that need to be overcome in further scaling down electronic circuits beyond a certain point. The reason why DNA could be useful in nanotechnology for the design of electric circuits is the fact that it actually is the best nanowire in existence - it self-assembles, it self-replicates and it can adopt various states and conformations. Not surprisingly, performing reliable experiments on a single oligo-DNA molecule is an extremely delicate task as partly contradicting research reports demonstrate: Different DNA transport experiments have shown that DNA may be insulating, semiconducting, or metallic. Among the numerous factors that could impact the results are the quality of the DNA-electrode interface, the base pair, the charge injection into the molecule, or environmental effects such as humidity or temperature. Researchers have now demonstrated a novel carbon nanotube-based nanoelectronic platform as proof of concept that single DNA molecules can be detected. This novel detection technique is based on change in electrical conductance upon selective hybridization of the complementary target DNA with the single stranded probe attached to the system. The single-stranded sequence-specific probe DNA whose ends are modified with amine is attached between two carbon nanotubes/nanowires using dielectrophoresis (DEP). This platform can be used for understanding how electrical charge moves through DNA which could help researchers understand and perhaps develop a technique for reversing the damage of DNA done by oxidation and mutation.

DNA, the blueprint of life, and electronics seem to be two completely different things but it appears that DNA could offer a solution to many of the hurdles that need to be overcome in further scaling down electronic circuits beyond a certain point. The reason why DNA could be useful in nanotechnology for the design of electric circuits is the fact that it actually is the best nanowire in existence - it self-assembles, it self-replicates and it can adopt various states and conformations. Not surprisingly, performing reliable experiments on a single oligo-DNA molecule is an extremely delicate task as partly contradicting research reports demonstrate: Different DNA transport experiments have shown that DNA may be insulating, semiconducting, or metallic. Among the numerous factors that could impact the results are the quality of the DNA-electrode interface, the base pair, the charge injection into the molecule, or environmental effects such as humidity or temperature. Researchers have now demonstrated a novel carbon nanotube-based nanoelectronic platform as proof of concept that single DNA molecules can be detected. This novel detection technique is based on change in electrical conductance upon selective hybridization of the complementary target DNA with the single stranded probe attached to the system. The single-stranded sequence-specific probe DNA whose ends are modified with amine is attached between two carbon nanotubes/nanowires using dielectrophoresis (DEP). This platform can be used for understanding how electrical charge moves through DNA which could help researchers understand and perhaps develop a technique for reversing the damage of DNA done by oxidation and mutation.

Dec 28th, 2007

As a critical component of optoelectronic devices, transparent conductive coatings pervade modern technology. The most widely used standard coating is indium tin oxide (ITO), used in nearly all flat panel displays and microdisplays. Causing problems for manufacturers, though, Indium is expensive and scarce and demand is increasing. From the depressed levels of $60/kg in 2002, indium prices rose to over $1,000/kg during the summer of this year. Recently, prices have fallen back to between $400-$500/kg. But, geologists say the cost of indium may not matter soon, because the earth's supply of this element could be gone within just a few years. In addition to the limited availability of Indium there are other reasons that make ITO and other metal oxides such as FTO (fluorine tin oxide) increasingly problematic for electronics manufacturers: the instability of these metal oxides in the presence of acid or base; their susceptibility to ion diffusion into polymer layers; their limited transparency in the near-infrared region; and lastly, the current leakage of FTO devices caused by FTO structure defects. This has made the search for novel transparent electrode materials with good stability, high transparency and excellent conductivity a crucial goal for optoelectronic researchers. Recent work by researchers in Germany exploits ultra-thin transparent conductive graphene films as window electrodes in solar cells.

As a critical component of optoelectronic devices, transparent conductive coatings pervade modern technology. The most widely used standard coating is indium tin oxide (ITO), used in nearly all flat panel displays and microdisplays. Causing problems for manufacturers, though, Indium is expensive and scarce and demand is increasing. From the depressed levels of $60/kg in 2002, indium prices rose to over $1,000/kg during the summer of this year. Recently, prices have fallen back to between $400-$500/kg. But, geologists say the cost of indium may not matter soon, because the earth's supply of this element could be gone within just a few years. In addition to the limited availability of Indium there are other reasons that make ITO and other metal oxides such as FTO (fluorine tin oxide) increasingly problematic for electronics manufacturers: the instability of these metal oxides in the presence of acid or base; their susceptibility to ion diffusion into polymer layers; their limited transparency in the near-infrared region; and lastly, the current leakage of FTO devices caused by FTO structure defects. This has made the search for novel transparent electrode materials with good stability, high transparency and excellent conductivity a crucial goal for optoelectronic researchers. Recent work by researchers in Germany exploits ultra-thin transparent conductive graphene films as window electrodes in solar cells.

Dec 17th, 2007

We have written plenty of Spotlights so far on carbon nanotubes and nanoelectronics. For instance, carbon nanotube (CNT) transistors have the potential to outperform state-of-the-art silicon devices. Researchers around the world have been working for years on advances at the device level, things like switches and wires and optimizing individual CNT transistors. More recently, scientists have begun to integrate nanotechnology-based materials and devices into larger systems - a crucial step in getting nanotechnology from the lab to the fab. Last year, for instance IBM reported to have built the first complete electronic integrated circuit around a single carbon nanotube (An integrated logic circuit assembled on a single carbon nanotube). Researchers in California have now reported another step towards showing nanoelectronics in systems: They have developed the world's first working radio system that receives radio waves wirelessly and converts them to sound signals through a nano-sized detector made of CNTs. Although this is only the demonstration of a single critical component (the CNT as demodulator) of an entire radio system, it is entirely possible that at some point in the future all components of a working radio could be nanoscale, thus allowing a truly nanoscale wireless communications system (apart from the magnitude of the technological achievement, this is probably great news for surveillance freaks, not so much for privacy advocates).

We have written plenty of Spotlights so far on carbon nanotubes and nanoelectronics. For instance, carbon nanotube (CNT) transistors have the potential to outperform state-of-the-art silicon devices. Researchers around the world have been working for years on advances at the device level, things like switches and wires and optimizing individual CNT transistors. More recently, scientists have begun to integrate nanotechnology-based materials and devices into larger systems - a crucial step in getting nanotechnology from the lab to the fab. Last year, for instance IBM reported to have built the first complete electronic integrated circuit around a single carbon nanotube (An integrated logic circuit assembled on a single carbon nanotube). Researchers in California have now reported another step towards showing nanoelectronics in systems: They have developed the world's first working radio system that receives radio waves wirelessly and converts them to sound signals through a nano-sized detector made of CNTs. Although this is only the demonstration of a single critical component (the CNT as demodulator) of an entire radio system, it is entirely possible that at some point in the future all components of a working radio could be nanoscale, thus allowing a truly nanoscale wireless communications system (apart from the magnitude of the technological achievement, this is probably great news for surveillance freaks, not so much for privacy advocates).

Oct 29th, 2007

Nanoelectronics deals with functional electron devices, such as transistors, in the nanoscale range size. As the name implies, nanoelectronics runs on electricity, i.e. the transport of electrons. Another approach to creating faster,smaller and more energy-efficient electronics is to move the field of optical information processing towards the nanoscale. Optical nanoelectronics will work with light instead of electron transport. Here the usual circuit elements such as inductors, capacitors and resistors could be created in order to operate using infrared or visible light. Using nanotechnology, researchers are able to create structures that could operate on the same or smaller scale as the wavelength of light (the wavelength of visible light is roughly between 400 and 700 nanometers). Going beyond 'conventional' nanoelectronics, researchers have now proposed a form of optical circuitry in which a network of subwavelength nanoscale metamaterial structures and nanoparticles may provide a mechanism for tailoring, patterning, and manipulating optical electric fields in a subwavelength domain, leading to the possibility of optical information processing at the nanometer scale.

Nanoelectronics deals with functional electron devices, such as transistors, in the nanoscale range size. As the name implies, nanoelectronics runs on electricity, i.e. the transport of electrons. Another approach to creating faster,smaller and more energy-efficient electronics is to move the field of optical information processing towards the nanoscale. Optical nanoelectronics will work with light instead of electron transport. Here the usual circuit elements such as inductors, capacitors and resistors could be created in order to operate using infrared or visible light. Using nanotechnology, researchers are able to create structures that could operate on the same or smaller scale as the wavelength of light (the wavelength of visible light is roughly between 400 and 700 nanometers). Going beyond 'conventional' nanoelectronics, researchers have now proposed a form of optical circuitry in which a network of subwavelength nanoscale metamaterial structures and nanoparticles may provide a mechanism for tailoring, patterning, and manipulating optical electric fields in a subwavelength domain, leading to the possibility of optical information processing at the nanometer scale.

Oct 16th, 2007

The most common type of modern transistor, and the type of transistor used in integrated circuits, is called a field-effect transistor (FET). The FET is so named because it relies on an electric field to control the shape and hence the conductivity of a 'channel' (the charge carrier) in a semiconductor material. This field causes a second electrical current to flow across the semiconductor, identical to the first weak signal, but stronger. Since the invention of the first transistor in 1947, the vast majority of electronic devices have been based on inorganic semiconductors, which in most cases has been silicon. Due to the demand for lightweight, flexible opto-electronic devices such as displays, solar cells and lasers, organic materials have become an important new class of semiconductor as they combine the virtues of plastics, which can be easily shaped, with those of semiconductors which are the basis of all microelectronics. Organic field-effect transistors (OFETs) have been mainly based on two types of semiconductors: conjugated polymers and small conjugated molecules. A recent review, published in Chemical Society Reviews, provides a general introduction about the current standing in the area of OFETs focusing on the new processable small molecules that have been recently reported for their use as organic semiconductors.

The most common type of modern transistor, and the type of transistor used in integrated circuits, is called a field-effect transistor (FET). The FET is so named because it relies on an electric field to control the shape and hence the conductivity of a 'channel' (the charge carrier) in a semiconductor material. This field causes a second electrical current to flow across the semiconductor, identical to the first weak signal, but stronger. Since the invention of the first transistor in 1947, the vast majority of electronic devices have been based on inorganic semiconductors, which in most cases has been silicon. Due to the demand for lightweight, flexible opto-electronic devices such as displays, solar cells and lasers, organic materials have become an important new class of semiconductor as they combine the virtues of plastics, which can be easily shaped, with those of semiconductors which are the basis of all microelectronics. Organic field-effect transistors (OFETs) have been mainly based on two types of semiconductors: conjugated polymers and small conjugated molecules. A recent review, published in Chemical Society Reviews, provides a general introduction about the current standing in the area of OFETs focusing on the new processable small molecules that have been recently reported for their use as organic semiconductors.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed