| Posted: Dec 17, 2012 | |

Nanotechnology in the cement industry - a patent analysis |

|

| (Nanowerk Spotlight) Cement is one of the most widely used materials in construction industry. In 2011, the expected total worldwide production of cement was 3,400 million tonnes. China is the largest producer accounting for 2 billion tonnes in production with India in second position (210 million tonnes) followed by the USA (68 million tonnes)1. | |

| Despite being widely used, cement-based materials have poor mechanical properties and are highly permeable to water and other aggressive chemicals, which reduces their durability. Moreover, the cement industry is one of the significant sources of CO2 emissions, which accounts for 5-6% of global man-made CO2 emission annually. However, the increasing demand for high performance structural materials and components has led to the rapid development of new classes of materials. | |

| Nanotechnology can play a significant role in the construction industry and stands at eighth position in terms of most significant areas of applications in nanotechnology2. | |

| Nanoengineering of cement-based materials can result in outstanding or smart properties. Introduction of nanotechnology in cement industry has the potential to address some of the challenges such as CO2 emissions, poor crack resistance, long curing time, low tensile strength, high water absorption, low ductility and many other mechanical performances. | |

| A remarkable improvement in the mechanical properties and durability of cementitious materials can be observed with incorporation of nanomaterials such as nano-SiO2, ZnO2, Al2O3, TiO2, carbon nanotubes, nano-clays, carbon nanofibers and other nanomaterials. | |

| Patent Analysis | |

| The current patent analysis has been conducted to get an overview of patent landscape for nanotechnology applications in cement industry, with focus on identifying nanomaterials for property enhancement, emerging trends, the major assignees, and applications in this area. All keywords relevant to cementitious materials along with possible synonyms, abbreviations were collected by studying full text of selected patents, which exactly relate to the concept of hydraulic cements. | |

| Growth in Patents | |

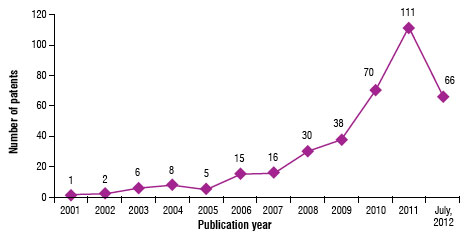

| The analysis of patenting activity pertaining to nanotechnology applications in cement industry resulted in 368 patents. Figure 1 depicts the patenting trend in the field of nanotechnology applications in cement industry. A sharp increase in year wise publication of granted/published patents can be observed from 2007 onwards due to the commercial success in using nano-scale materials as cementitious ingredients. The tally of 154 granted patents from a total list of 368 patents clearly shows a high output of commercialization and research in this field. | |

|

|

| Fig. 1: Yearwise patent publication trend for nanotechnology applications in cement industry. | |

| Nano-enabled Cement Patent Classification | |

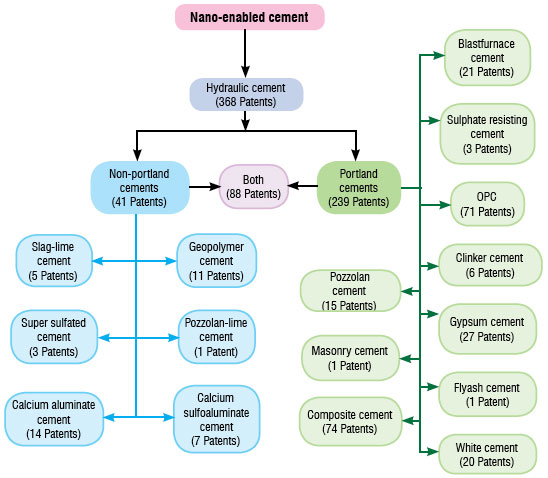

| The patent analysis is restricted to nanotechnology applications in hydraulic cement (cement that will set and harden after being combined with water). Nanomaterials are widely used in portland cement industry (prepared by heating clay and limestone in a kiln and pulverizing the mixture) when compared to non-portland cements, which can be clearly observed from the number of patent filings in both classes. Majority of patents are filed in the area of composite cement (74 patents) and ordinary portland cement (OPC) (71 patents) respectively, followed by gypsum-based cement with 27 patent filings. | |

|

|

| Fig. 2: Classification of patents based on the type of nano-enabled cement. | |

| Geographical Distribution | |

| China is the world leader of patent filings, their 154 patent applications contributing 41% of overall filings, representing the major and active R&D player in the area of nano-based cementitious materials. South Korea is the second leading country with 55 patents (15% of patent filings) on nano-enabled cement, closely followed by United States with 51 patents. Russia, Germany, Japan, France and India are the other leading patent filing countries with 37, 18, 11, 9 and 5 patents respectively, while the remaining patents represent a minor contribution from rest of the world. | |

| Assignee Analysis | |

| Dagestan State University (Russia) is the leading assignee with 15-patents to its credit, which are mainly focussed on the development of heat resistant and high compression strength concrete materials. Halliburton Energy Services Inc (USA) comes second with 14-patents that are directed towards well bore cementing for the gas, oil or water wells using nano-cementitious materials. Other major assignees are either universities or companies from China. Among all the assignees, companies contribute 60% (221 patents) of the total patents filed on nanotechnology applications in cement industry worldwide, indicating a high rate of commercialization and R&D on a large scale, while universities/academic institutes own 24% (89 patents) of patents while rest of the patents are filed by individual inventors. | |

| Technology Analysis | |

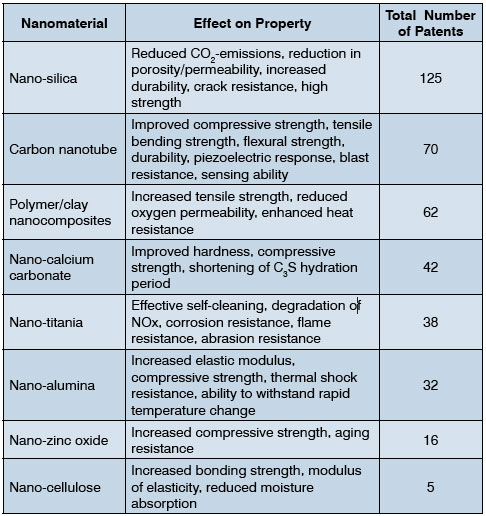

| Introduction of nanoscale materials into cementitious materials has emerged as a promising solution for enhancing the properties and performance of cement materials. A list of various nanomaterials that are added to cement as fillers along with their effect on properties are given in Table 1. | |

|

|

| Table 1: Various nanomaterials that are incorporated in cement and their effect on properties. | |

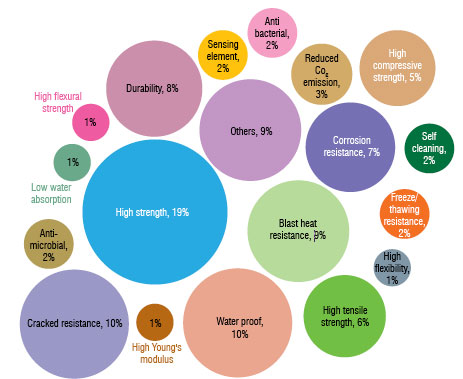

| The patents are segregated with respect to the characteristic property imparted by incorporated nanomaterials and is represented in the form of a bubble chart as shown in Fig. 3 below. The percentage of patents given in the chart is based on the size of the bubble i.e. bigger size indicates greater number of patent filings corresponding to that specific attribute. | |

| The analysis shows that nanomaterials are mainly incorporated to enhance various mechanical properties of cementitious materials. Introduction of carbon nanotubes (CNTs) in cement results in the improvement of various mechanical properties and also imparts sensing characteristics to the cement. However, the poor dispersion of CNTs is a major obstacle in achieving good mechanical performance in a composite. Effective methods for dispersion of CNTs such as ultrasonication and use of a surfactant are discussed in the prior art for the preparation of high strength concrete. | |

| Nano-silica is increasingly being used as a replacement for micro-silica in cement industry. Because of its high reactivity and ultra fine nature, it is commonly used in concrete mixes in large quantities, thereby reducing the cement content by 40% resulting in less CO2 emissions and environmental contamination. Incorporation of nano-silica in cement slurry gives enhanced mechanical properties, lower porosity and permeability, which are crucial factors for increased durability. | |

|

|

| Fig. 3: Bubble chart showing the percentage-wise distribution of patents based on characteristic property imparted by the added nanomaterials. | |

| Nano-titania is well known for its chemical stability and low toxicity. Moreover, it acts as an oxidizing agent at near UV-radiation. Concrete containing nano-titania showed effective self-cleaning property and it is used as a major component in polymer cement mortar for photo-catalytically degrading nitrogen oxide (NOx) and other pollutants. | |

| Nano-alumina is widely used in cement mortar for increasing the elastic modulus of the cementitious material. The alundum-mullite pouring product has high compressive strength, good washing resistance, corrosion resistance and high thermal shock resistance, and can withstand rapid temperature changes. | |

| Addition of calcium carbonate to cement-based aqueous composite provides improved hardness and abrasion resistance to concrete. The compressive strength of composition containing nano-calcium carbonate increased by at least 25% and showed 40% improvement in fluid loss, as compared to a cement composition without the nano-calcium carbonate. | |

| Calcium carbonate is also used as a nano modifier for reducing C3S hydration induction period resulting in improved resistance to high temperature degradation of concrete. Polymer-clay nanocomposites show an improvement in mechanical properties and barrier properties of nano-enabled cement. | |

| Nano-silica, carbon nanotubes, nano-calcium carbonate, nano-titania, nano-alumina and polymer/clay nanocomposites are the most commonly used nanomaterials. These nanomaterials are mainly used to enhance various mechanical properties of the cementitious materials such as crack resistance, corrosion resistance, tensile strength and compressive strength. | |

| Conclusions | |

| The first patent on nano-enabled cement was published in 1996 and since then the patenting activity has continuously increased with an exponential rise after 2007. China has emerged as the major contributor in this area with 41% of global patents filings. It is also interesting to note that 60% of the patents are filed by corporates showing a clear trend of high rate of commercialization. | |

| The emergence of nanotechnology in cement industry has already shown a remarkable impact on mechanical properties of cementitious materials with patented commercial products such as Cor-Tuf®, HuberCrete®, Alpol, Nycon-G Nano etc. are already available in market. These products have shown a significant improvement in tensile strength, corrosion resistance, crack resistance, heat resistance, high strength and many other mechanical properties of the cementitious materials. Moreover, nanotechnology can help to overcome major environmental challenges faced by the conventional cement materials, making them more environmental friendly with reduced CO2 emissions and long durability. | |

| Though the application of nanotechnology in cement industry is an emerging area, the trends in patent data indicate that commercial adaptation of this technology has already been started and in the near future nano-enabled cement is poised to occupy the cement industry in a big way. | |

| References | |

| 1. minerals.usgs.gov/minerals/pubs/mcs/2012/mcs2012.pdf | |

| 2. A.K. Mukhopadhyay, "Next-generation nano-based concrete construction products: A review", In K. Gopalakrishnan, B. Birgisson, P. Tylor, N. A-Okhine (Eds.) "Nanotechnology in civil infrastructure", p 207-223, Springer ( 2011), ISBN 978-3-642-16656-3 | |

| By MD Shakeel Iqbal ([email protected]) and Yashwant Mahajan ([email protected]), CKMNT. | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|