| Posted: Nov 12, 2010 | |

Nanotechnology in the automotive industry |

|

| (Nanowerk Spotlight) Nanotechnology will play a major role in the car industry; but don't hold your breath to see anything like the Volkswagen Nanospyder futuristic concept car anytime soon. This entrance to the 2006 Los Angeles Design challenge was supported by hydrogen fuel cells, solar power, wheel-mounted electric motors and inflatable organic body panels combine to form the unusual shape of the two-seater concept. | |

| According to its creators – designers based at the Volkswagen Design Center in Santa Monica – the Nanospyder would be formed out of a latticework of billions of tiny programmable nano devices measuring less than half a millimeter in diameter. Each of these tiny devices can be programmed to be as strong or weak as required meaning active crumple zones can be created. Clothing the nano-lattice are panels formed out of a mix of organic materials some of which can inflate to provide further cushioning in the result of an impact. The material doubles as a power source as polysynthesis generates small amounts of electricity. This coupled with hydrogen fuels generates power to drive the tiny electric motors mounted within the hubs of all four wheels. | |

|

|

| OK, back to today. The automotive sector is a major consumer of material technologies – and nanotechnologies promise to improve the performance of existing technologies significantly. Applications range from already existing – paint quality, fuel cells, batteries, wear-resistant tires, lighter but stronger materials, ultra-thin anti-glare layers for windows and mirrors – to the futuristic – energy-harvesting bodywork, fully self-repairing paint, switchable colors, shape-shifting skin. | |

Nanotechnology for cars |

|

| The basic trends that nanotechnology enables for the automobile are | |

|

|

|

|

|

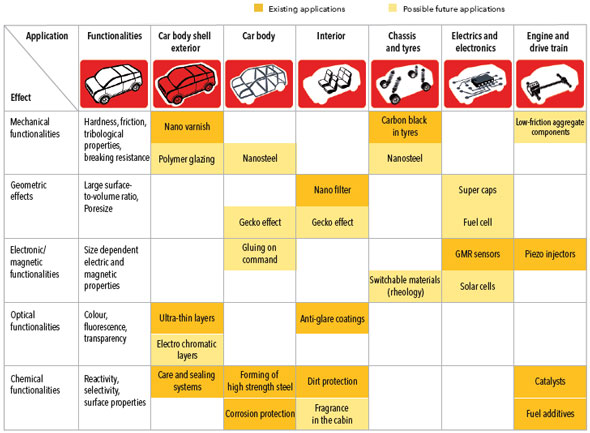

| Applications of nanotechnologies in automobiles. (Source: Hessian Ministry of Economy, Transport, Urban and Regional Development) | |

| Where will nanotechnology take us in the automotive sector? The following examples are but an overview of a large number of efforts and applications involving nanotechnologies in the automotive industry: | |

Nanotechnology for Chassis and exterior |

|

| Vehicle weight reduction is a key part of car manufacturers' strategies to improve fuel economy. Ford's "Atoms to Engines" team for instance looked at the structure of cast aluminum alloys at near atomic levels. From this work, a detailed analysis of the structure/property/process relationship of the aluminum alloy engine blocks has led to reduced engine weight and, in turn, increased fuel efficiency. | |

| Another area is the substitution of mineral glass windows by polymers. However, until recently some key performance specifications had not been reached; scratch resistance and long term ultraviolet resistance remained challenges. Recent advances involving nanotechnology are helping polycarbonate window developers to overcome these challenges. | |

| Nanoengineered thermoplastic materials allow a weight reduction of up to 40% compared to traditional steel chassis parts. | |

| With regard to paints and surface coatings, nanostructured surfaces result in improved paint adhesion and color durability. Self-cleaning will become standard on windscreens and car body shells. Scratch-resistant, dirt-repellent, UV-resistant and self-healing car paints are applications that already exist or are in development. | |

Nanotechnology in Tires |

|

| Tires are one of the early applications of nanostructured materials in automobiles. Carbon black was the first nanomaterial to be used by the automotive industry in tires as a pigment and reinforcing agent. | |

| The key to tire performance is the mixture of the rubber – but its optimization requirements can be contradictory (highly complex chemical and physical interactions between the rubber and the filler material): While the tire needs good grip its rolling resistance has to be low as well. | |

| Some 30% of the tire cover consists of reinforcing filler which makes possible wanted properties such as grip, abrasion resistance,resistance to initial wear and tear, and tear propagation. There are three products that significantly improve the properties of natural rubber: soot, silica and organosilane. Now being produced in nanoscale form, these particles as well as the cross-linking with the natural rubber molecules play a key role for tire properties. | |

| Researchers have also printed carbon nanotube sensors that monitor tire wear in real time. | |

Nanotechnology for Automobile Propulsion |

|

| Building an electric car needs to take into account four basic requirements – powerful and safe energy storage to give the car a sufficient driving range; engines and associated electronic components that make best use of the stored onboard energy; light-weight components to compensate for the (at the moment still) extra weight of the batteries; and all that at a price that can compete with gasoline-powered automobiles. | |

| Lithium ion batteries are currently being intensively developed worldwide for use in electric vehicles. The consensus view among researchers is that the battery will be of the lithium-ion type, but which of the lithium-ion chemistries to use is still a major question. | |

| Nanotechnology holds great promise for improving the performance and life-times of the Li-ion batteries. It also has the potential to enhance the energy and power density, shorten the recharge time, as well as decrease the size and weight while improving safety and stability of the batteries. A large number of companies such as Altair Nanotechnologies, mPhase Technologies, A123 Systems, Li-Tec Battery GmbH, NanoEner Technologies, Next Alternative Inc., Nexeon Ltd. etc. are actively pursuing the development of nano-enabled batteries while some others are already producing them (see here for an overview of major producers/developers of nano-based batteries and their product range). | |

| Nanotechnology is also key to improving fuel cell performance of future generations of hydrogen-powered cars. | |

| One of the leading fuel cell technologies developed, in particular for transportation applications, is the proton exchange membrane (PEM) fuel cell, also known as polymer electrolyte membrane fuel cells – both resulting in the same acronym PEMFC. These fuel cells are powered by the electrochemical oxidation reaction of hydrogen and by the electroreduction of the oxygen contained in air. | |

| Although nanotechnology promises cheap bipolar materials using nanocomposites, more efficient non-platinum electrocatalysts, and thermally stable and more durable membranes to become available in the near future, the precious metal platinum still remains the workhorse of PEM fuel cells. One way to minimize platinum usage is to increase catalytic efficiency by nanostructuring the platinum metal; another way of eliminating the use of platinum altogether is by exploring the use of much cheaper non-precious metal catalysts where the nanostructured surfaces match or exceed the catalytic properties of platinum. | |

Nanotechnology under the hood |

|

| For fuel cell cars, hydrogen sensors will be a critical component for safety and widely needed. They will detect leaks long before the gas becomes an explosive hazard. Researchers have already developed thin, flexible hydrogen sensors using nanostructured materials, i.e., single-walled carbon nanotubes decorated with palladium nanoparticles. | |

| Of course, we will be stuck with gas-guzzling cars for quite some time to come. Improved fuel efficiency and the reduction of harmful exhaust emissions are two key areas where nanotechnology applications will make an impact. | |

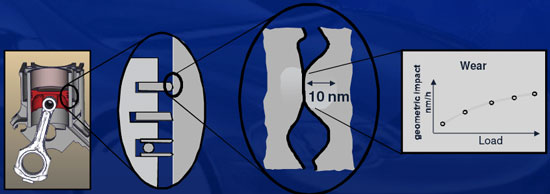

| In today's automobiles, 10-15 per cent of the fuel consumption is influenced by engine friction due to the friction loss at the moving mechanical parts (piston, crank drive, valve drive). Nanocoatings applied to mechanical parts, and nanostructured lubricants, help reduce friction and abrasion and thereby improve fuel efficiency. | |

|

|

| The tribological processes at the piston/cylinder wall interfaces take place at the nanoscale. (Source: Daimler AG Research & Development) | |

| Another example of the many aspects of the above-mentioned "Atoms to Engines" project by Ford is developing a thermally sprayed nanocoating that could replace the heavier cast iron liners that provide the necessary wear resistance of cylinder bores in aluminum block engines. This thin wear-resistant coating reduces weight and improves friction performance while delivering equal durability and reliability to the product. | |

| Piezo fuel injection technology is now used not only in diesel engines, but also in their petrol counterparts. In the case of direct injection, a pump first builds up high pressure before it shoots the fuel finely dosed into the combustion chamber of the cylinder via a nozzle. The precision with which this happens directly influences the combustion process. The higher the pressure and the more precisely the dose and time of injection can be controlled, the more efficient fuel combustion will be. Nanocrystalline piezoelectric materials will improve these piezoelectric materials. | |

| For exhaust cleaning in petrol-powered cars, systems based on three-way catalysts are used. These can convert the three main pollutants or pollutant types – carbon monoxide, nitric oxides and hydrocarbons – as far as possible and thus remove them from the exhaust gas. During the conversion of toxic to non-toxic gases nanotechnologies play a crucial role. The impact of catalysts generally depends on the size of the surface. | |

| If the material used for the catalytic function is scaled to the nanometer range, the specific surface increases drastically. The composition and structure are chosen such that exhaust gases interact optimally with the catalytically active coating, and their chemical transformation into harmless substances is accelerated. | |

Interior |

|

| Car interior application will mostly deal with comfort issues – dirt-repellent and antimicrobial textiles and surfaces, nanoparticulate air filters, anti-glare coatings of mirrors and instruments. Or how about climate-controlled car seats based on thermoelectrics – materials that convert electricity directly into heating or cooling. | |

Electric systems and electronics |

|

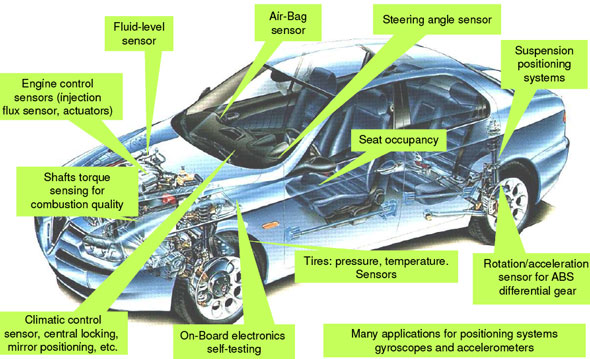

| Electronics is an innovation driver in the automotive sector as more and more components are being controlled electronically, electromechanically or electromagnetically. Nanostructured actor components could substitute current microsystems technology-based direct injection systems for instance. | |

| Spintronics promises to revolutionize computing. While conventional complementary metal-oxide semiconductors (CMOS), a technology used today in all types of electronics, rely on electrons' charge to power devices, the emerging field of spintronics exploits another aspect of electrons – their spin, which could be manipulated by electric and magnetic fields. With the use of nanoscaled magnetic materials, spintronics or electronic devices, when switched off, will not have a stand-by power dissipation problem. With this advantage, devices with much lower power consumption, known as non-volatile electronics, can become a reality. | |

|

|

| Spintronics applications in cars. (Source: Centro Ricerche FIAT) | |

| The quickly emerging hybrid car sector not only uses batteries to store energy for the electric drive mode, it also pushes recuperation technologies, i.e. the re-use of braking energy. Here, the moving energy is converted into electrical current via generator during braking and stored in accumulators or super or ultra capacitors. Nanotechnologies are expected to have a major impact in this area. For instance, scientists are already producing ultra-lightweight, bendable batteries and supercapacitors in the form of everyday paper. | |

| Micro-structured solar cells can already be integrated into sunroofs and are offered as options on some cars. Using nanostructured and flexible plastic solar cells with a thickness of less than 1 micron, it will become possible to cover larger areas of the car exterior with solar energy harvesting thin-films. | |

| The overall electrical to optical efficiency for lighting applications in today's cars is only about 1%. This will be considerably improved by the development of diffractive and microoptics, new light sources, and their integration with the power supply. | |

NanoMobil |

|

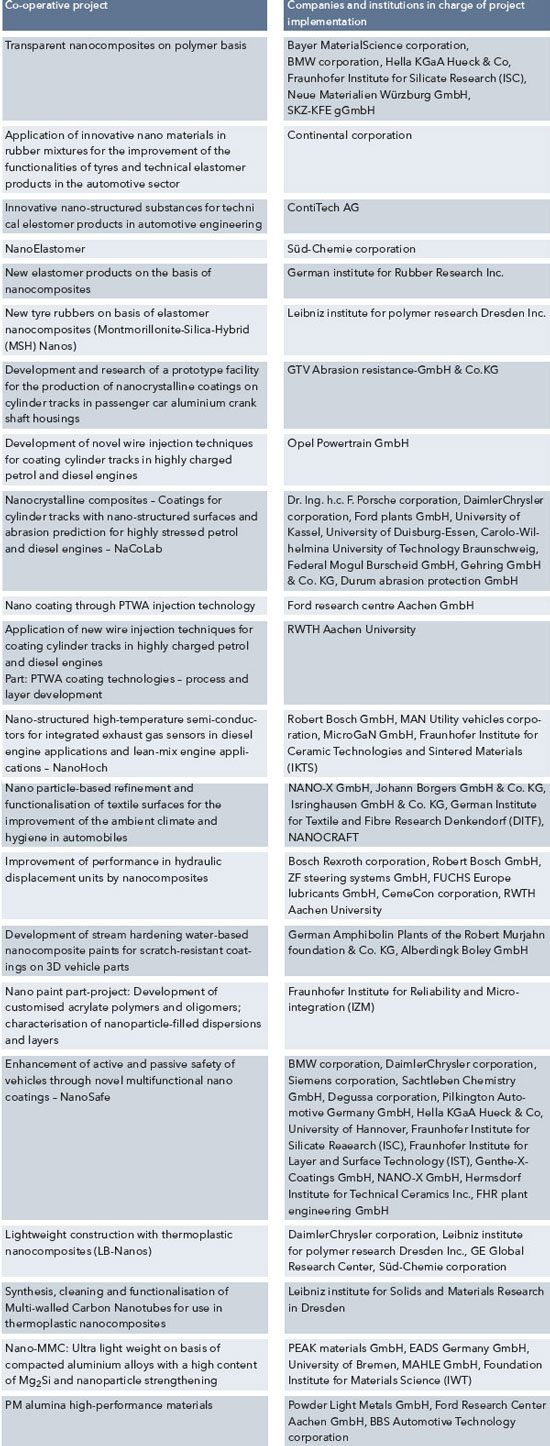

| In 2004, Germany, through its Federal Ministry of Education and Research (BMBF), established a specific nanotechnology funding program – NanoMobil – in connection with automotive technologies and in order to keep the German car industry and its suppliers competitive. Numerous research institutes, suppliers and automotive companies have been participating in several interdisciplinary projects. The following chart shows the range of topics covered by NanoMobil and gives an indication of the wide range of nano-applications within the automotive sector: | |

Funded projects within the lead innovation project NanoMobil. Funded projects within the lead innovation project NanoMobil.

|

|

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|